The current situation

Automatic component replacement and retrofit projects focus on the local replacement of imported AC drives in industrial rolling mill systems. They cover three typical scenarios: Hot rolling, cold rolling in a single rack, and cold rolling in a plate strip. The original parts replacement process depends on imported equipment, which involves long lead times, high costs, and complicated maintenance. The retrofit solution ensures cost reductions and efficiency while ensuring production continuity through seamless replacement, structural compatibility, and performance optimization.

1

Lead times for purchasing are long and incur extra expenses.

1

Typical modifications involve alterations to the cabinet structure, re-wiring, or modifications to the host machine program. Resulting downtime can be very long

1

The original system communication protocol can be old and sensitive to interference. Speed control accuracy of the rolling mill (such as cold-rolling jacket control of the plate belt) can be affected.

Solution details

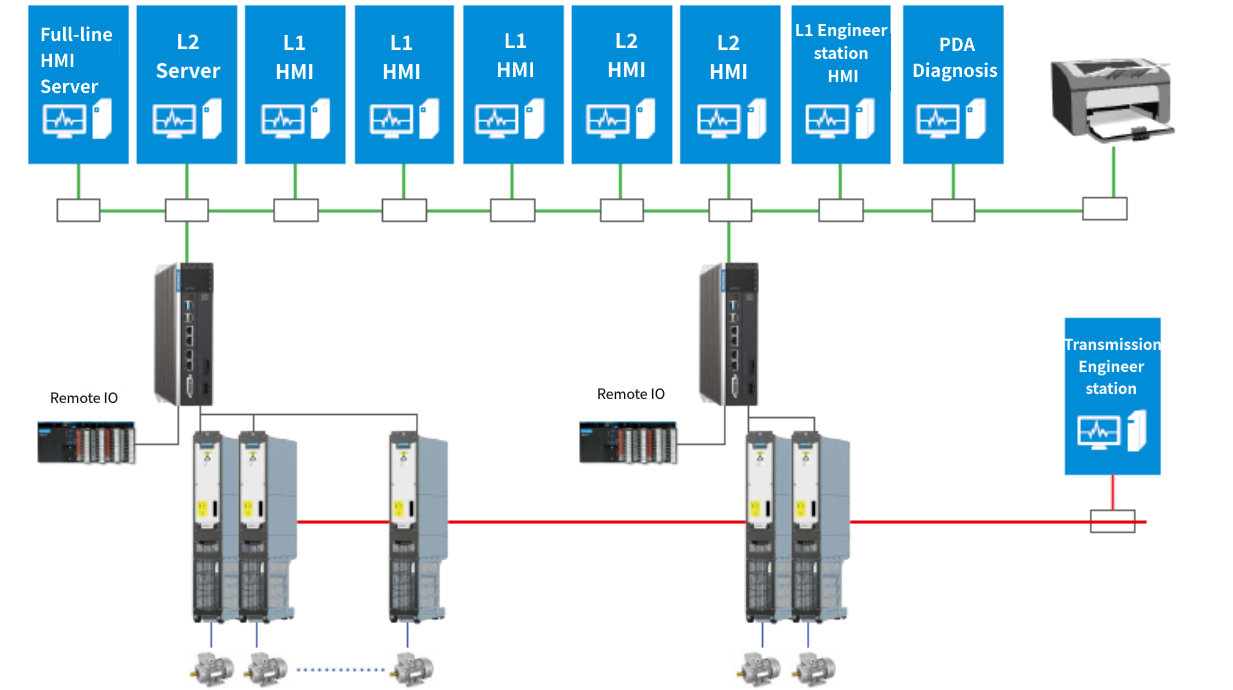

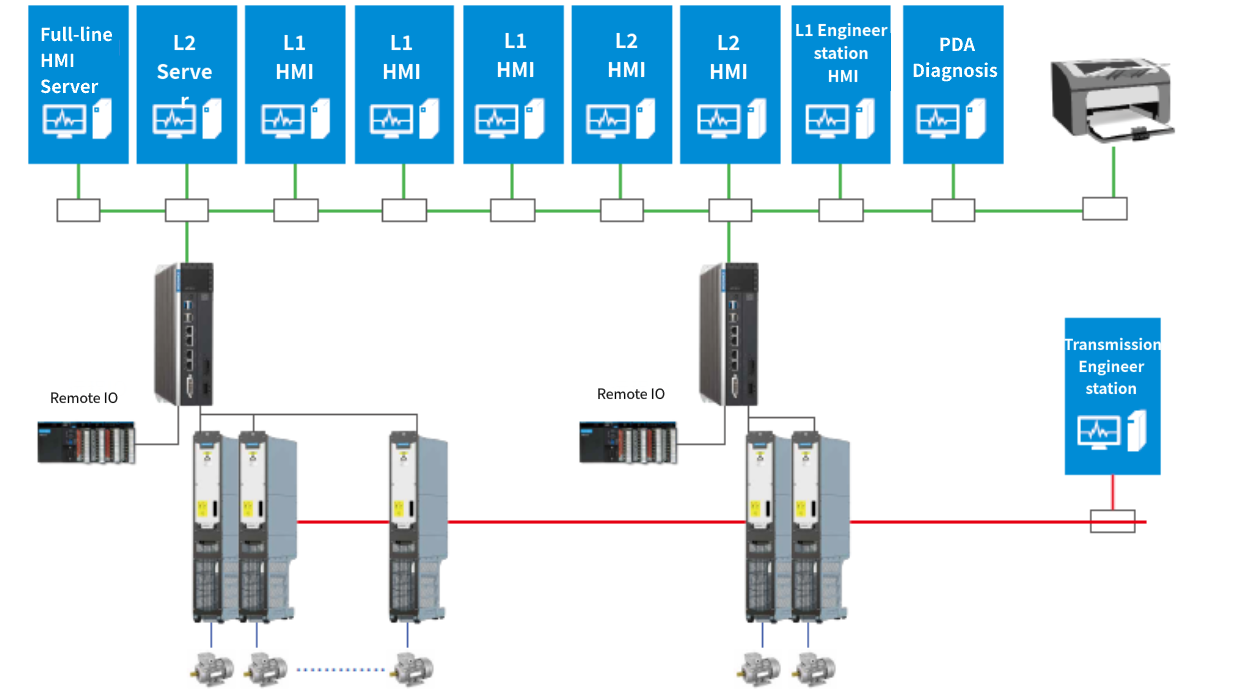

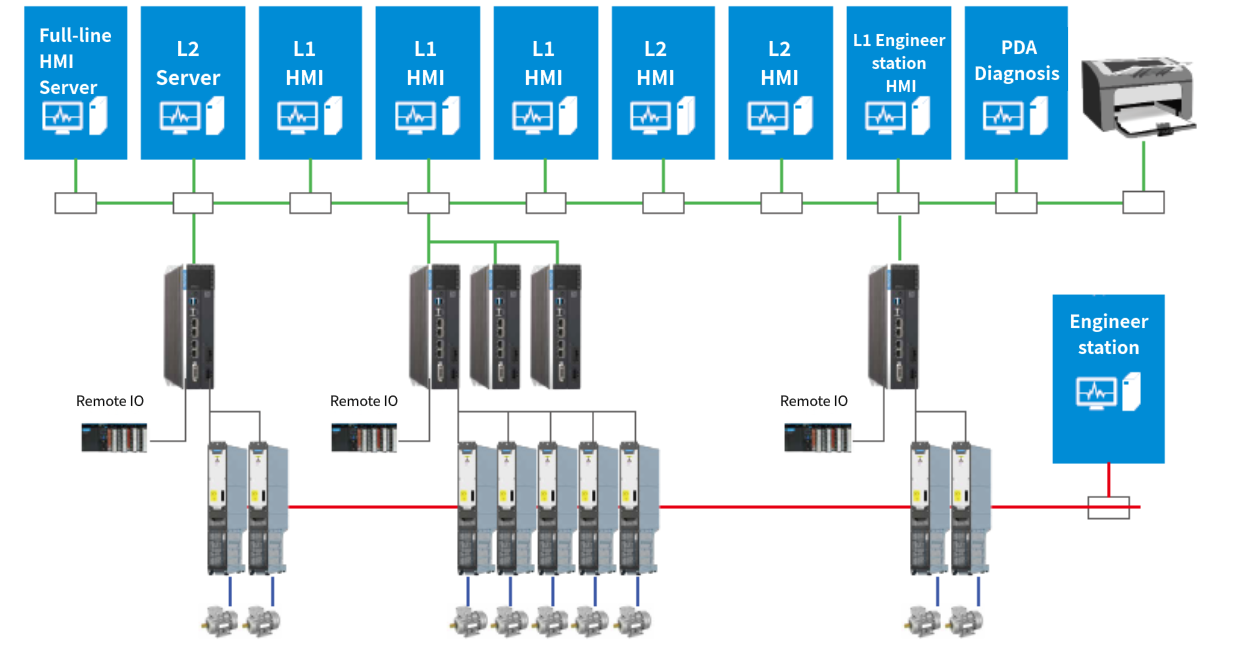

Solution ①: Main drive, auxiliary drive, basic rectifier + inverter; 11–1500 kW (17 main drives) 1.5 times heavy load mode with a rated torque amplitude of 150%; Encoder forms FVC closed-loop vector control mode to ensure speed fluctuation and speed stability accuracy;Solution ②: Regenerative rectifier + Inverter replacement; Rolling speed: 200/400 m/min, maximum rolling force: 1200 T; Main drive: 900 kW*4;Solution ③: Full-line main drive such as unwinder, S-roller, and sleeve; Feedback rectifier + inverter; Power 690 V2700, 400 V3.7 to 355 kW。

Log out reminder

Log out reminder