Quality optimization and loss reduction

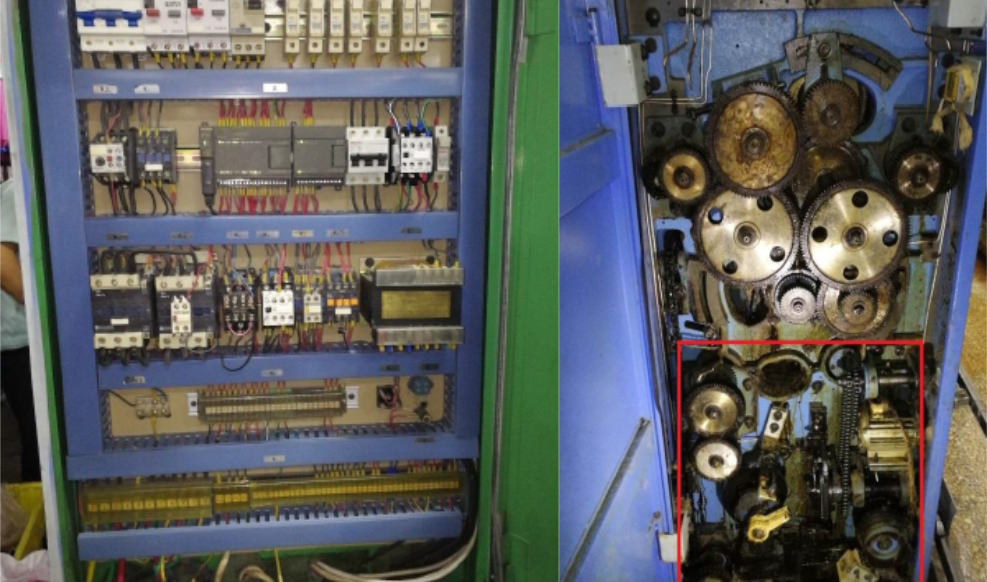

The steel collar process is highly automated, requiring less labor and reducing the cut-off rate by 30%.

Upgrading the technology results in increased production capacity.

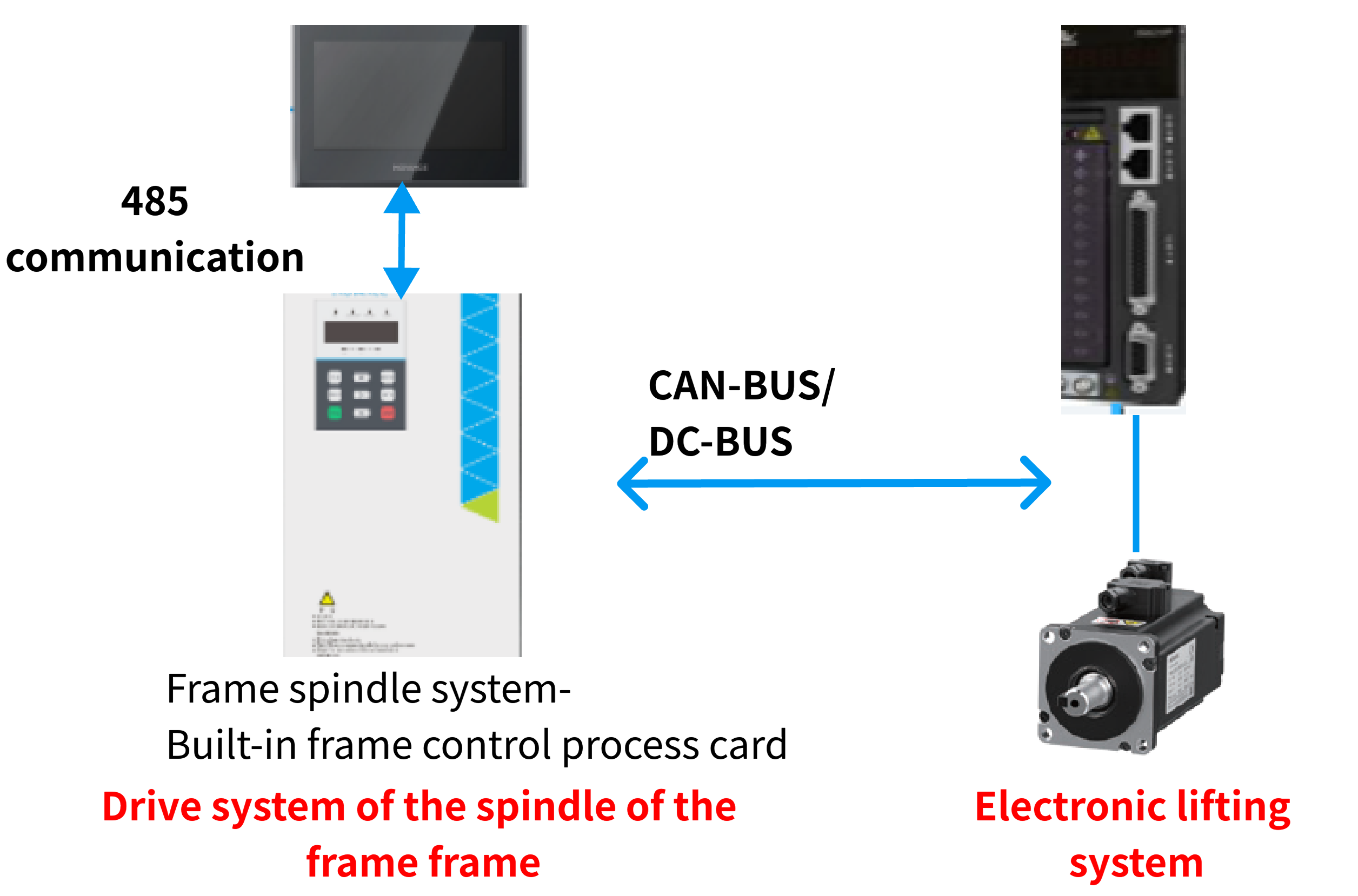

Electronic cam replacemes mechanical cam, improving precision and aesthetics, and increasing production capacity by 5%.

Improve production efficiency and product quality

The speed of automatic tether rewinding is increased by 10%. Keeping the reel unwound reduces the dewinding rate by 90%.

Easy process adjustment

The molding process is easy to adjust, in order to improve efficiency.

Log out reminder

Log out reminder