Log out reminder

Log out reminder

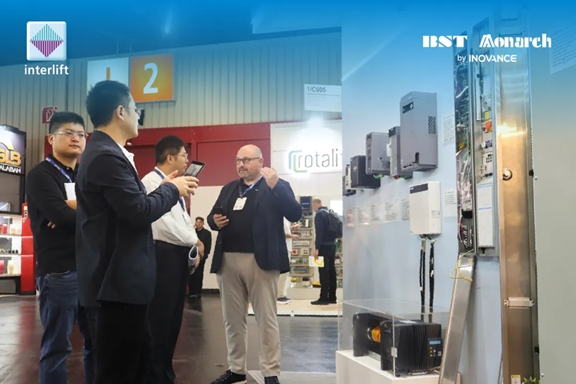

Inovance closed Interlift 2025 under the banner "Green Innovation · Local Creation", unveiling a portfolio tailored to Europe’s small-shaft, machine-room-less (MRL) elevators and underscoring the company’s near-market manufacturing capability in Hungary.

The exhibits addressed three regional challenges: limited shaft space, high labour costs, and stringent energy targets.

- ML20 door-frame inverter (100 x 100 mm) fits inside the door jamb, allowing commissioning from the landing for faster, safer installation. A graphical secondary-development toolkit lets OEMs add bespoke functions in minutes.

- ML40 four-quadrant drive debuts a reactor-free topology that eliminates audible hum while achieving THDi < 5% and standby power below 5 W, in line with upcoming EU eco-design goals.

- Aurora home-lift package integrates motor, drive, brake, and encoder into a four-in-one traction unit. Its A4-size control box and PES wiring scheme reduce shaft cabling by roughly 50%, simplifying retrofits and enhancing ride comfort.

All products are manufactured at Inovance’s facility in Szekesfehervar, Hungary, enabling local stock, shorter lead times, and lower transport-related emissions.

During the show, Inovance signed a development memorandum with a leading Southern European elevator OEM for a custom ML40 variant and initiated sample-testing programmes with several European system integrators. A multinational customer delegation also toured the Hungarian plant, launching a joint "COP 0-to-1" co-production initiative.

“By pairing ultra-compact, energy-saving hardware with local manufacturing, we help elevator makers deliver greener, quieter, and more space-efficient solutions — exactly what Europe’s urban landscapes demand,” said Inovance Europe’s Industry General Manager.